Table of Contents

When it comes to building a strong, reliable roof, what’s underneath matters just as much as what’s on top. While shingles or tiles get most of the attention, it’s the plywood foundation that truly carries the load — literally! Choosing the right plywood can mean the difference between a roof that weathers storms for decades and one that quickly falls victim to leaks, sagging, or costly repairs. Whether you’re tackling a new construction project or replacing an aging roof, understanding the best types of plywood for roofing is your first step toward creating a structure that’s built to last. Let’s dive into the top choices and discover what makes them stand out above the rest.

What is Plywood and Why is it Used for Roofs?

Credit: duroply.in

Plywood is an engineered wood product made by bonding several layers of wood together, with each layer’s grain running at right angles to the adjacent one. This cross-grain pattern enhances strength, making plywood an excellent choice for demanding applications like roof decking and roof sheathing.

Moreover, for roofs, plywood provides a solid, durable surface that supports shingles or other roofing materials, helps maintain structural integrity, and withstands weather conditions. Its versatility and strength are why it’s a top pick for a range of roofing projects.

Benefits of Using Plywood for Roofing Projects

Using plywood for roofing comes with numerous advantages:

Structural Integrity

Due to its multi-layered design, plywood sheathing provides excellent strength and load-bearing capability, which is essential for withstanding snow, wind, and heavy rains.

Durability

With proper installation and moisture protection, plywood can last for decades, reducing the need for frequent roof repairs.

Flexibility

Because plywood can be easily cut and shaped, it adapts well to different types of roofs and roofing projects, whether flat or pitched.

Moisture Resistance

Especially with options like exterior plywood and CDX plywood, your roof will have a greater resistance to moisture infiltration, a major cause of roofing failures.

Ease of Installation

It’s relatively easy to install plywood, even for DIY enthusiasts, due to its manageable weight and standard sizes.

Best Types of Plywood for Roofing

Not all plywood is created equal, especially when it comes to roofing. The best types are those specifically designed to withstand the elements and provide solid support.

CDX Plywood

Credit: rocplex.com

CDX plywood is the most commonly used plywood for roofing projects, especially in residential construction. The “C” and “D” refer to the grades of the plywood’s two sides:

- C-grade: One side is of a medium-grade quality with some visible defects.

- D-grade: The other side has more visible imperfections.

The “X” in CDX stands for “exposure,” indicating that this plywood is designed to handle exposure to moisture temporarily (like during construction), but it’s not waterproof.

Why It’s Great for Roofing

- Durable and Strong: Sufficient strength for standard roofing needs.

- Cost-Effective: Offers good performance at a reasonable price point.

- Widely Available: Found in virtually every building supply store.

Best Use

- Underlayment for asphalt shingles

- Residential homes in moderate climates

Moreover, CDX must be covered with roofing felt and shingles quickly after installation because it’s not designed for prolonged exposure to rain.

Exterior-Grade Plywood

Credit: plyonline.com.au

Exterior-grade plywood (sometimes called EXT plywood) is specifically made for outdoor use. It is constructed using waterproof adhesives and higher-quality wood veneers, making it much more resistant to moisture and temperature fluctuations than standard plywood.

Why It’s Great for Roofing

- Superior Moisture Resistance: Handles exposure to rain, snow, and humidity better than CDX.

- Long-Term Durability: Less prone to delamination and warping.

- Versatile: Works well under various roofing materials (shingles, metal, tiles).

Best Use

- Roofs in areas prone to heavy rain, snow, or high humidity

- Roofs requiring extended construction timelines

Pressure-Treated Plywood

Credit: capitalforest.com

Pressure-treated plywood is chemically treated to resist rot, decay, and insect infestations. This type of plywood is infused with preservatives under pressure to provide enhanced resistance against environmental hazards.

Why It’s Great for Roofing

- Excellent Longevity: Designed to last longer, especially in moist or termite-prone environments.

- Rot and Insect Resistant: Great for tropical and coastal areas.

- Durable: Performs better over time against moisture infiltration.

Best Use

- Roofs in coastal areas

- Roofs over high-humidity regions

- Structures with limited ventilation (like sheds, cabins)

Important Note: Pressure-treated wood can be heavier and more expensive than regular plywood. It’s also important to use corrosion-resistant nails or fasteners (like stainless steel) when working with it.

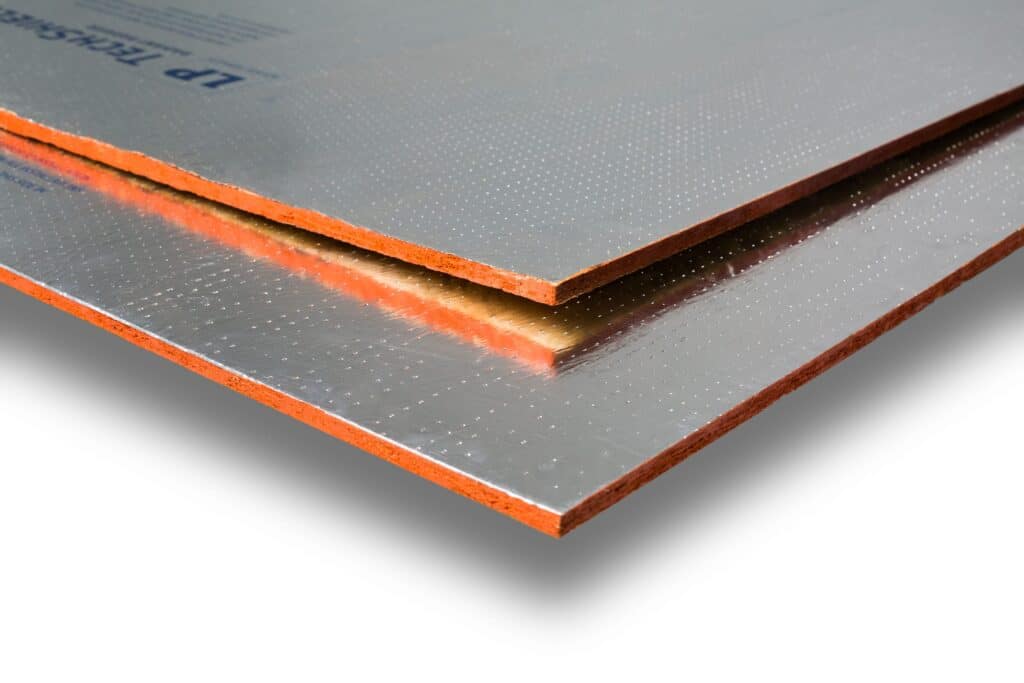

Radiant Barrier Plywood

Credit: lowes.com

Radiant barrier plywood is an innovative type of plywood that has a reflective foil layer attached to one side. This specialty plywood is designed to reflect radiant heat, helping to keep homes cooler by reducing attic temperatures.

Why It’s Great for Roofing

- Energy Efficiency: Helps reduce cooling costs significantly.

- Strong and Durable: Offers the same structural strength as regular plywood, with added thermal benefits.

- Environmentally Friendly: Reduces energy consumption.

Best Use

- Roofs in hot, sunny climates

- Homes aiming for energy efficiency certifications

Structural Plywood (Rated Sheathing)

Credit: bdcnetwork.com

Manufacturers create structural plywood, often called rated sheathing, to meet strict building standards for strength and load-bearing performance. They test and rate this type of plywood for its ability to handle heavy loads and stresses, such as the weight of roofing materials or environmental pressures like wind and snow.

Why It’s Great for Roofing

- Meets Code Requirements: Essential for projects where local codes dictate minimum structural performance.

- High Strength-to-Weight Ratio: Excellent for both residential and commercial roofing.

- Variety of Thicknesses: Available for light or heavy-duty applications.

Best Use

- Commercial buildings

- Homes in areas with heavy snowfall

- Roofs with complex designs need additional support

Marine-Grade Plywood (Optional for Specialized Roofing)

Credit: ilicut.com

Builders sometimes choose marine-grade plywood for premium projects, even though it’s not commonly used in standard residential roofing. This is a high-end, top-quality plywood made from durable hardwoods and waterproof adhesives. However, it’s extremely resistant to water damage, with no voids in its layers.

Why It’s Great for Roofing

- Superior Moisture Resistance: The ultimate in water durability.

- High-Quality Construction: No gaps or voids that could weaken the wood.

- Exceptional Longevity: Can last for decades even under harsh conditions.

Best Use

- Premium residential projects

- Roofs overboat houses, coastal mansions, or high-end commercial properties

- Areas with extreme, consistent exposure to moisture

Important Note: Marine-grade plywood is considerably more expensive than other types, making it impractical for most standard home roofing jobs.

Factors to Consider When Choosing Plywood for Roofing

Before making your final selection, keep these important considerations in mind:

Thickness

For roofing, plywood thickness usually ranges from ⅜ inch to ¾ inch, with ½ inch being standard. Thicker panels are necessary for heavier roofing materials or wider truss spacing.

Span Rating

The span rating shows how far you can space roof trusses or rafters without compromising the plywood’s structural integrity.

Local Weather Conditions

Areas prone to heavy rain, snow, hurricanes, or extreme heat require more specialized plywood like exterior-grade, pressure-treated, or radiant barrier plywood.

Budget

There is a trade-off between cost and performance. CDX offers a good balance, while exterior and marine-grade plywoods come at a premium for better durability.

Building Codes

Always check local building codes before purchasing. Some areas may specify the type and thickness of plywood you must use for roofing.

Final Thoughts

Selecting the best type of plywood for roofing is critical for the performance, safety, and longevity of your roof. For most residential projects, CDX plywood offers the best balance of affordability and strength. In harsher climates or special applications, exterior-grade, pressure-treated, or even radiant barrier plywood can provide the added durability and protection you need. Therefore, understanding the strengths and best uses of each plywood type will help you make a smart investment, ensuring your roof remains sturdy, safe, and reliable for many years to come.